Soon there will be avatars working on the assembly line

20 cameras, state of the art sensors and virtual reality glasses. It may look like the studio of a tech start up, but it isn’t; it’s SEAT’s biomechanics lab located in the CARS Health and Rehabilitation Centre in Martorell.

How does it work?

“Technology enables us to recreate the assembly line in our lab facilities. It’s essential that the worker performing the test realistically reproduce the exact motions they would make on the job” explains Sonia García, who is responsible for Ergonomics at SEAT. They measure two parameters in the lab – muscle exertion and the position of joints when carrying out specific movements. “Some workers perform the same motions up to 100 times a day, so job rotation and the design of the assembly line are crucial in order to prevent possible injuries”, she assures.

3D avatars like in a videogame

Two different technologies are used for the same purpose. One creates 3D avatars with a total of 20 cameras in combination with sensors that capture the motions the worker’s joints, and the analysis software uses the data to create an avatar. “The avatar is a 3D image which accurately reproduces both the speed and the range of motions. It’s the same technology used to create characters in a videogame, but it has a much higher level of accuracy”, explains Sonia.

Virtual reality, real impact

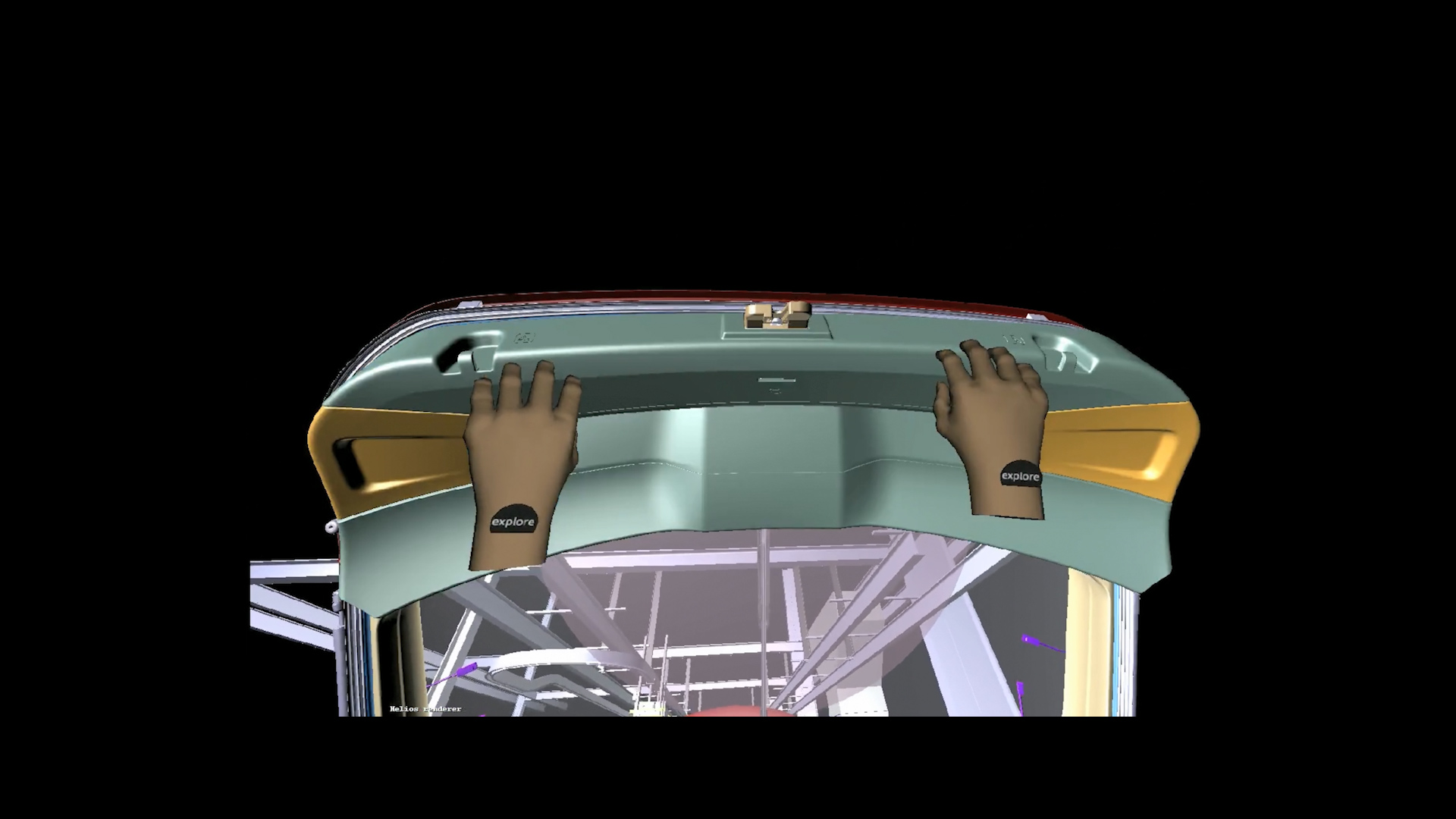

The second technology used is virtual reality. The major advantage of this system is that enables advance planning and the possibility of introducing modifications before the assembly line goes into operation. “We can simulate different positions until we find the best option, for example, for attaching the rear hatch. This allows us to save time as well as money in comparison to performing test son the actual assembly line”, Sonia points out.

How do the results get applied?

“Biomechanics immediately opens up new possibilities for actively designing new workstations” explains Dr. Patricia Such, who is responsible for Occupational Safety and Health at SEAT. The lab has been in operation since 2017, and over 4,000 studies have been carried out. “We’ve managed to reduce the rate of muscle injuries by 70% in just two years and aim to continue improving in the future”, points out Dr. Such. The data has helped, among others, to adapt the assembly line to the new SEAT Leon, lowering one of its sections by 20 centimetres. But the lab’s work does not stop when the line design has been completed. While production continues, workstations are constantly analysed to make further improvements.