DHL Supply Watch: Machine learning to mitigate supplier risks

Today, DHL introduced a new integral part of its Resilience360 supply chain risk management platform called DHL Supply Watch. The extension of DHL’s early warning system uses machine learning and natural language processing to detect disruptions in a company’s supply base before they cause financial losses or long lasting reputational damage.

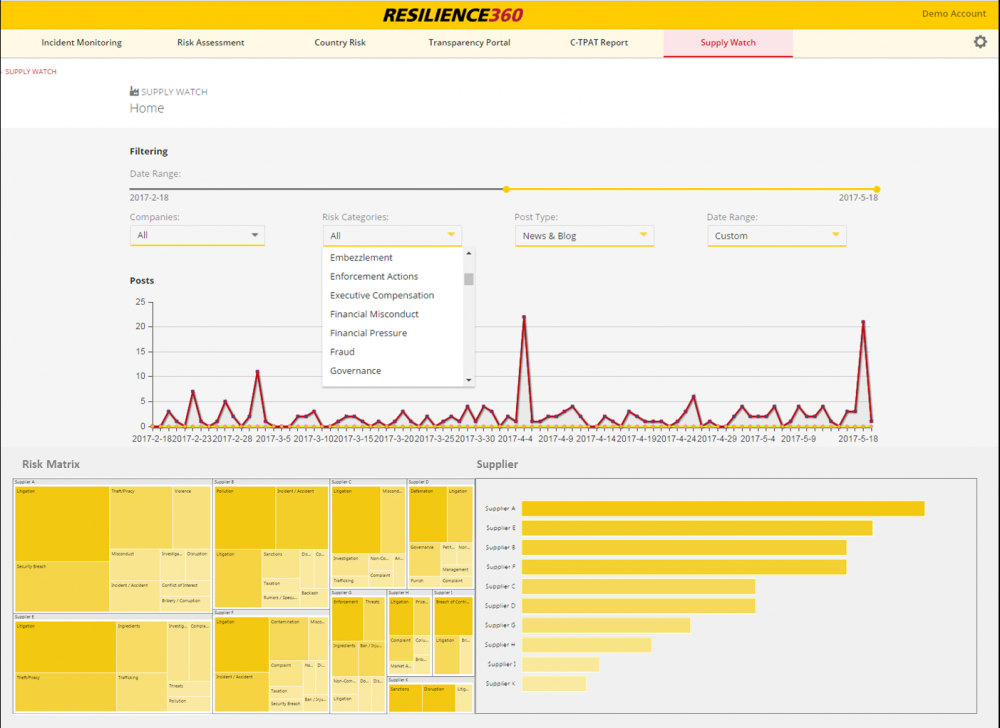

With Supply Watch, DHL Resilience360 is adding a broad range of new risk categories to the system’s existing portfolio to monitor supplier risks on a company level, including financial indicators, mergers & acquisition, environmental damages, supply shortages, quality issues and labor disputes, using publically available data found by monitoring of online and social media sources.

“We provide our customers with a solution that detects and mitigates potential supplier failures before they happen, allowing them to focus on early risk mitigation and auditing activities of their most relevant suppliers and third parties,” says Tobias Larsson, Head of Resilience360, DHL Customer Solutions & Innovation. “The insights and transparency customers gain through Supply Watch are another example of how digitalization can benefit end-to-end supply chain operations, through building resilient supply chains and enabling businesses to be more competitive.”

DHL Resilience360 Supply Watch monitors some 140 different risk categories including financial, environmental and social factors among risks resulting from crime, labor breaches, quality defects and supply chain perils such as shortages, capacity constraints and delays. Using advanced Machine Learning (ML) and Natural Language Processing (NLP) technologies, the adopted system analyzes data based on the monitoring of up to 30 million posts from more than 300,000 online and social media sources to detect potential supply chain disruptions.

Instances such as the bankruptcy of one of the world’s top ten container shipping lines, which led to capacity shortages and supply chain disruptions worldwide, was for many businesses unexpected, despite indications that were made public before. DHL Supply Watch closes this gap and flags potential risks at an early stage.

The recent global ‘WannaCry' ransomware attack is another example for a situation in which the system could help to identify which suppliers may have reportedly been affected, and therefore allowing companies working with them to take appropriate precautions in their supply chain.

The development of the intelligent Supply Watch system was supported by leading linguistics experts and data scientists to establish a reliable analysis of both content and context of online discussions. Supply Watch is capable of understanding human language and evaluates how people talk about risk-relevant events and situations around the world. Among different risk types which may affect supply chains, many are particularly hard to detect, such as quality issues.

Monitoring and analyzing discussions and articles in online and social media about such concerns, information about recalls, protest or delays, helps identify early indicators of supplier and partner distress. This feature distinguishes the system significantly from conventional search approaches as it operates nearly in real-time. The fast and effective solution enables users to address emerging issues quickly, preventing reputational and financial losses.

DHL Supply Watch is available independently but can be fully integrated into the DHL risk assessment and incident monitoring solution Resilience360.

DHL Resilience360 Supply Watch is being launched from the Gartner Supply Chain Executive Conference 2017 in Phoenix, Arizona, where participants have the opportunity to experience a live demonstration of the solution.

Source: DHL